-

PRODUCTS

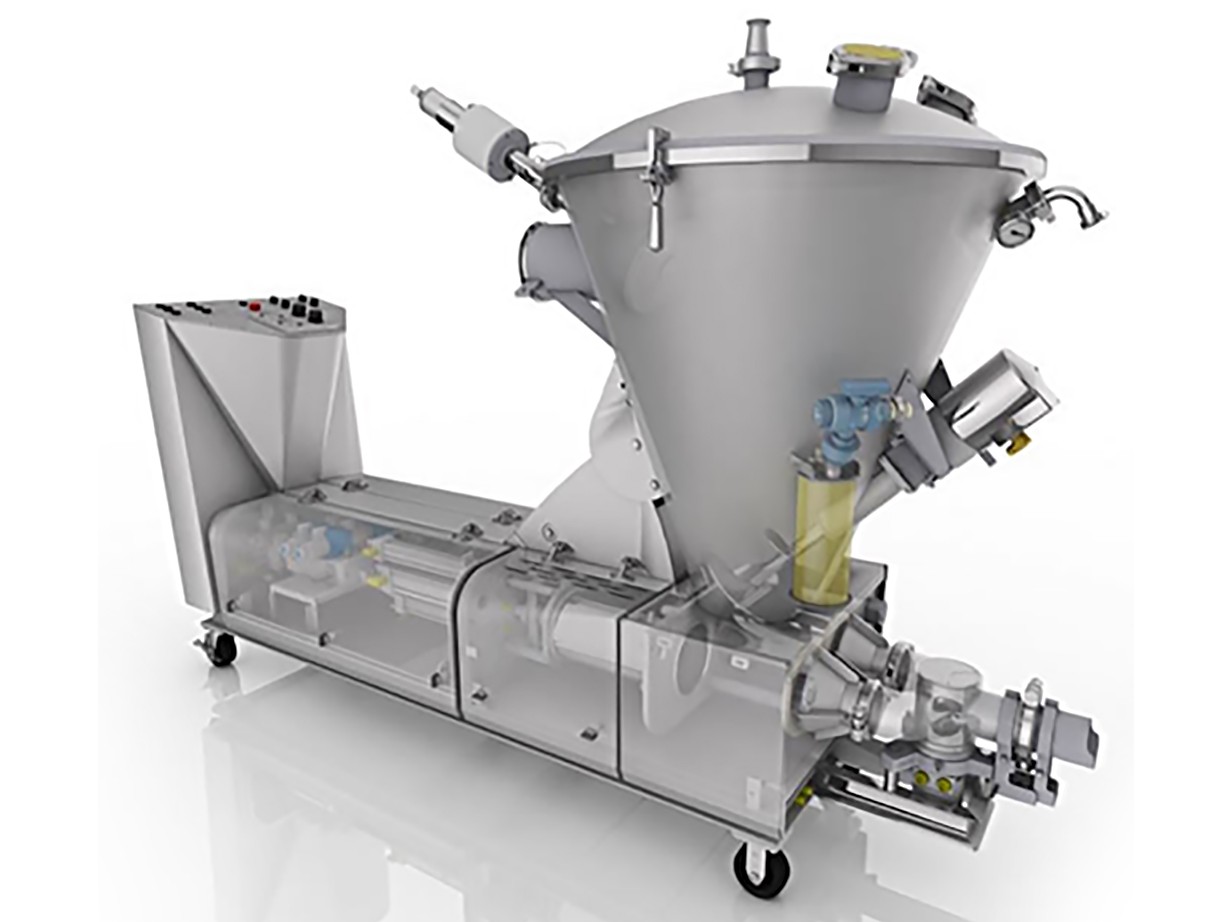

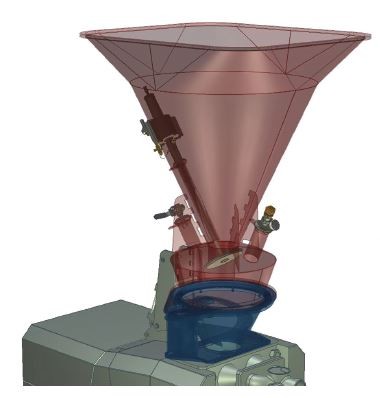

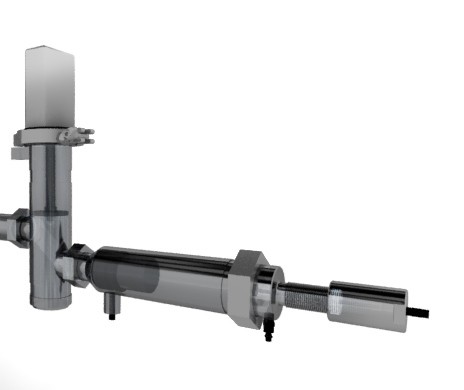

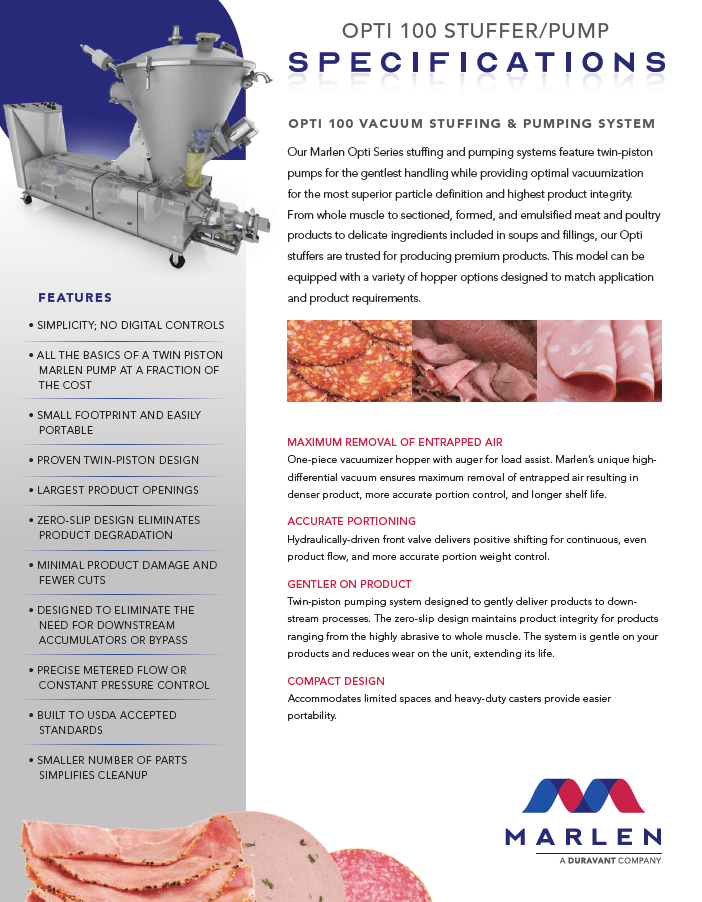

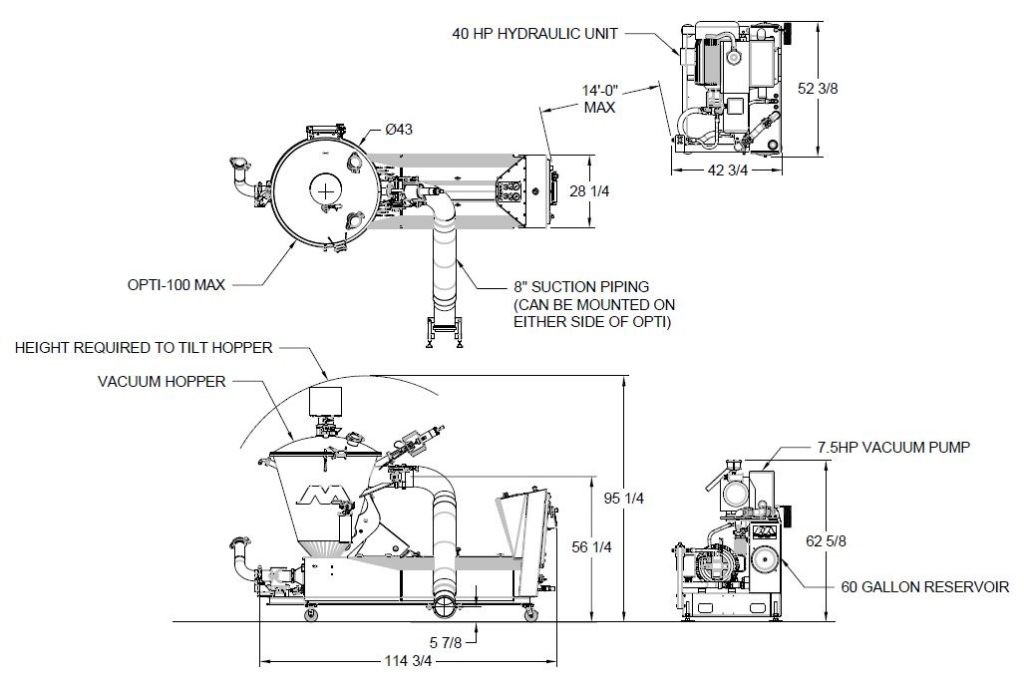

- Vacuum Stuffing, Pumping & Portioning

- Size Reduction – Slicers, Meat Dicers, Shredders, Meat Grinders, Jet Knives

- Industrial Filling Equipment

- Batch Ovens, Smokehouses, Chillers & Industrial Dehydrators

- Serpentine Cook/Chill Systems & Crust Freezers

- Linear Cookers & Air Fryers

- Spiral Ovens, Chillers & Freezers

- Searing, Roasting & Grill Marking Equipment

- Smoking, Browning & Braising Machines

- Pre-package Pasteurization

- Post-package Pasteurization

- Industrial Sous Vide Water Cooking & Chilling

- Food Handling & Plant Hygiene Equipment

- INDUSTRIES

- Resources

- SupportPro

- ABOUT MARLEN

- Contact