Home

- Products

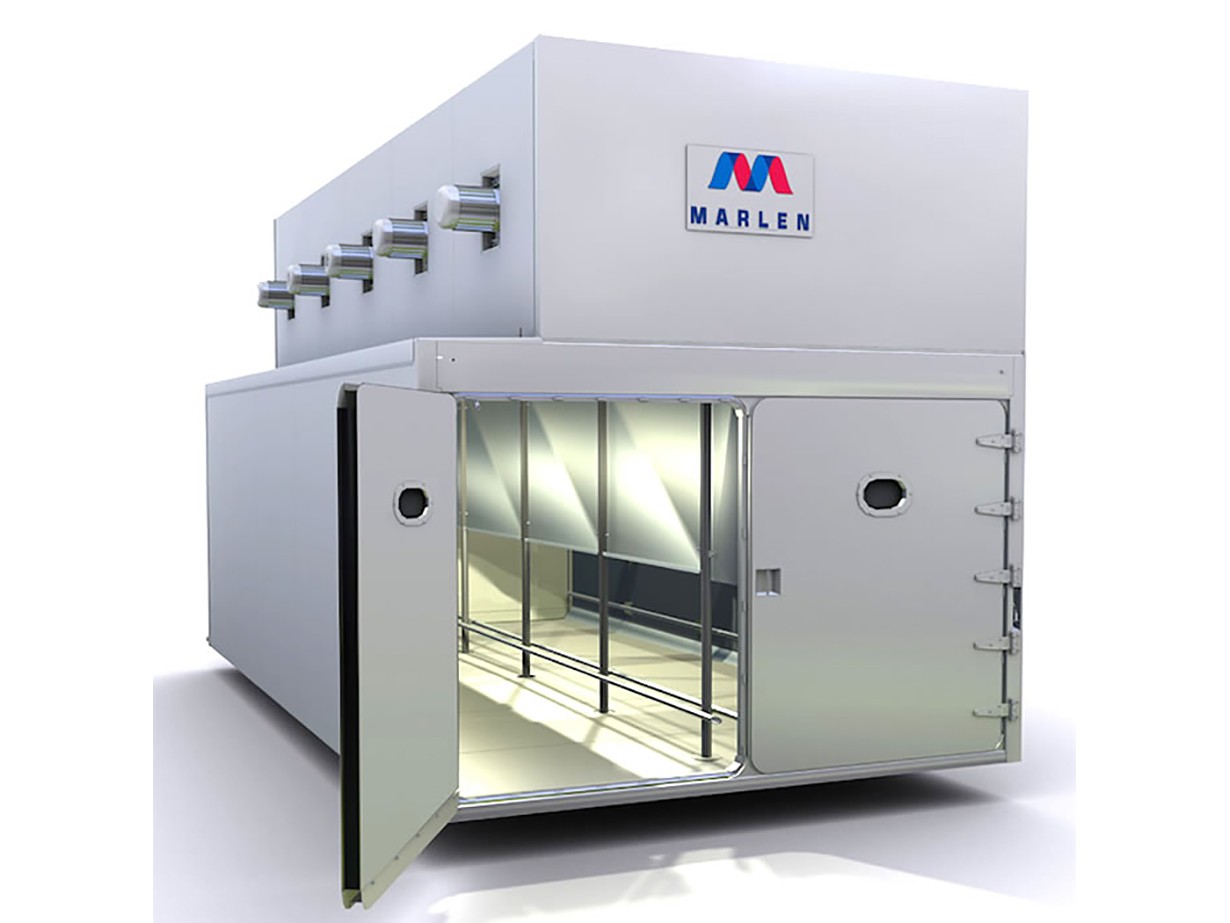

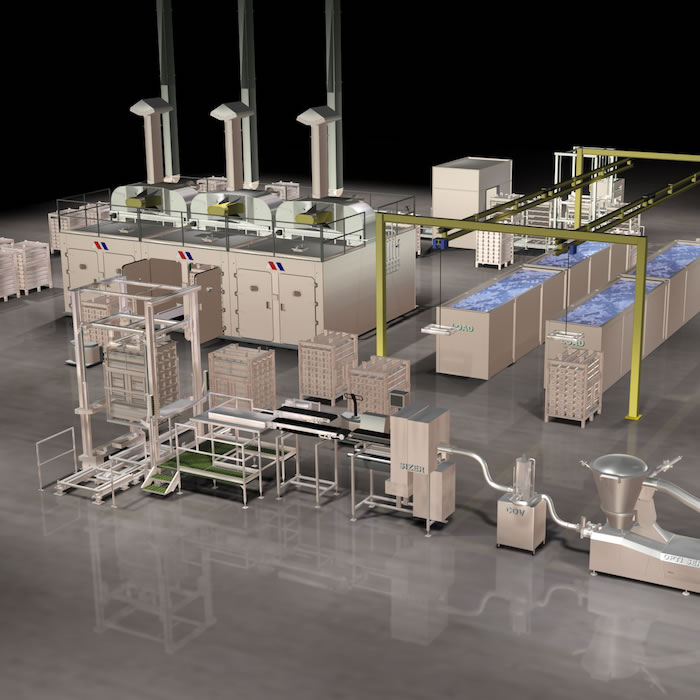

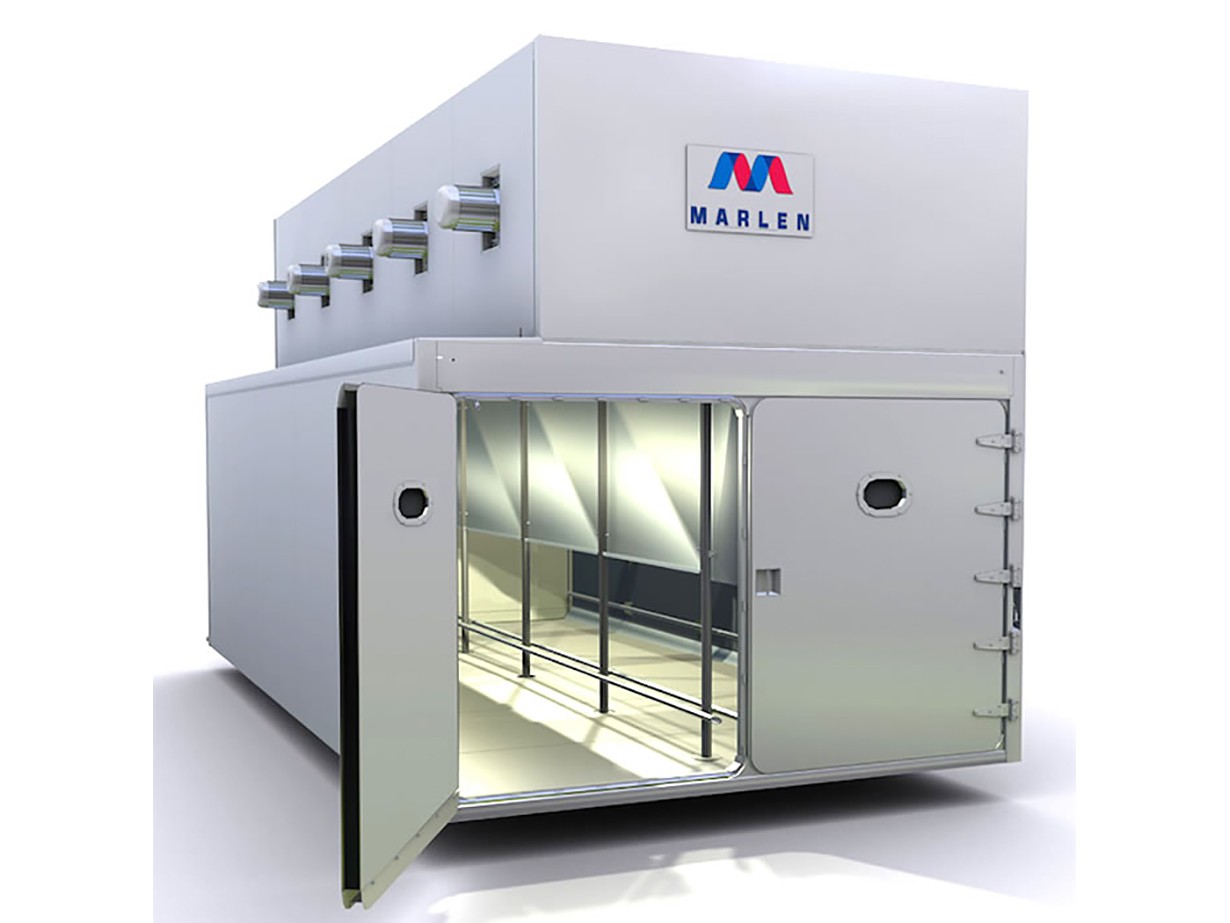

Batch Ovens, Smokehouses, Chillers & Industrial Dehydrators

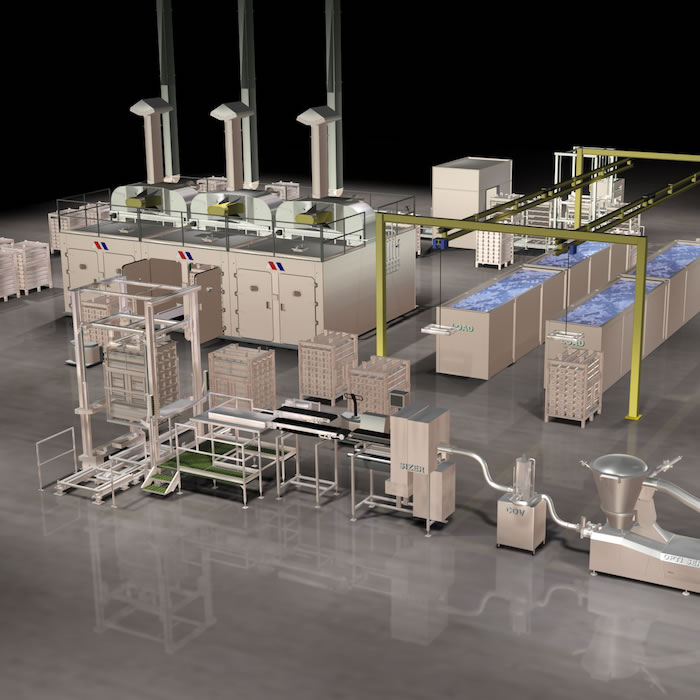

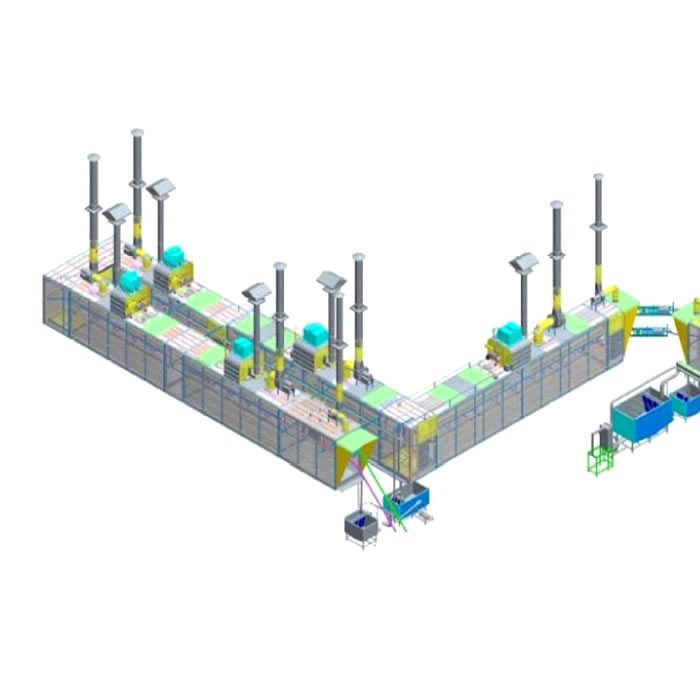

Marlen food processing equipment uses the most current technology and innovation to provide workable solutions for your cooking and chilling needs. Marlen batch thermal processing solutions include custom designed industrial smokehouses, food processing batch ovens and cookers as well as industrial dehydrators.

-

Custom designed around your product, process and facility, our food processing ovens, cookers, and industrial smokehouses provide a more uniform product with smart balance precision for process repeatability day after day. With full...

View Equipment →

-

Custom designed around your product, process and facility. Our industrial dehydrator provides a more uniform product, precise and repeatable results, complete data reporting, and easy access to serviceable areas. Visit our Riverside facility...

View Equipment →

-

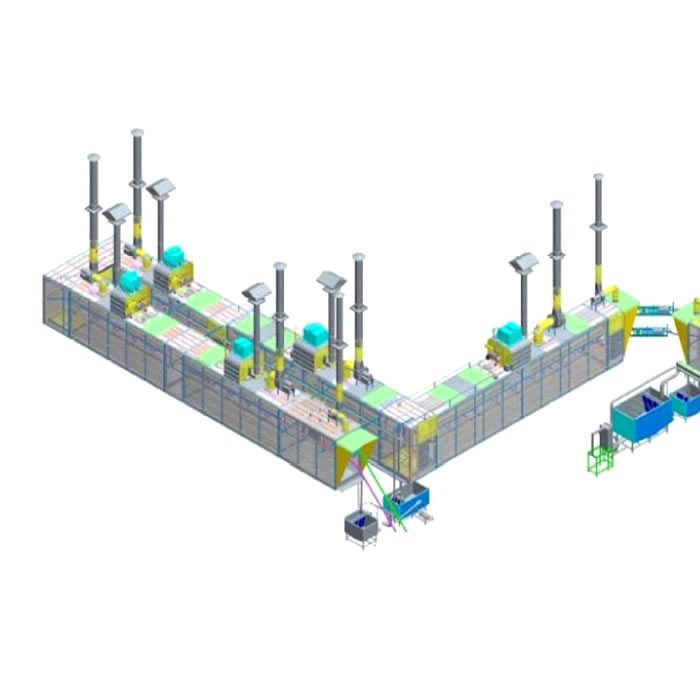

Our chillers feature a continuous chill process, allowing maximum heat reduction at a uniform rate, resulting in faster chill times, higher yields, and greater product uniformity while achieving maximum energy savings. Custom chilling...

View Equipment →

-

An efficient, ergonomically advanced forming system designed for molding product. It consistently forms product end-to-end.

View Equipment →

-

Designed to optimize product flexibility with production rates ranging between 5,000 to 20,000 lbs per hour.

View Equipment →