As food processors struggle to have enough workers to meet rising demand in this economy, inflation is causing grocery and retail prices to rise, which frustrates consumers. As summertime “revenge travel” occurs, studies show that 76% of Americans are likely to pack their own food instead of finding food during their trip. In addition, many consumers are looking for healthier options at the grocery store. More than half of consumers have reported that they are following a diet plan and have cited clean and mindful eating as reasons for it.

As consumers look for light and healthy dishes this summer that are pre-packaged for convenience and travel, there are many alternatives for ready-to-eat fish and seafood products that food processors can offer to capture consumer attention. Food processors will benefit from understanding Marlen’s unique solutions for industrial surface treatment, continuous thermal processing, and automatic volumetric filling. With Marlen as a process partner, food processors will be well-equipped to meet the moment and provide consistent results that are both appealing for consumers and that will reduce overall labor cost.

Develop the Perfect Surface Effects

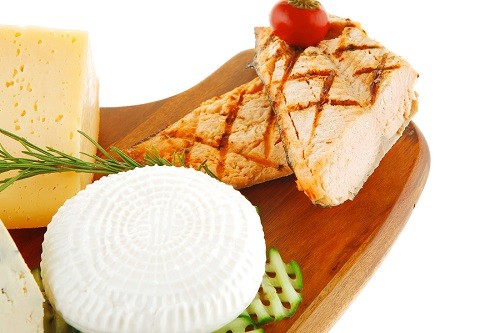

Industrial flame grilling with the Marlen Afoheat™ Flame Grill is perfect for developing surface texture and color on summer fish and seafood favorites. With multiple ribbon burners and an adjustable grill marker, the Flame Grill gives products an authentic “flame-grilled” appearance and taste. A dedicated ribbon burner heats the grill marker rings to a cherry-red color over 1,200°F (648°C). The floating ring design allows the rings to adjust to the specific contour of each product surface to ensure consistent marks and avoid puncturing the product surface, which leaves perfect grill marks on the surface of salmon filets, shrimp, and other seafood products. The Afoheat™ Flame Grill works well as a standalone unit, and it is designed to work together with a Marlen Spiral Oven to complete the cooking process.

Cook with Efficient Energy Transfer

Whether in Roast mode or Steam mode, the Marlen Spiral Oven maximizes the yield of various proteins that consumers will be taking with them during their summer travel. For example, after getting a flame-grilled appearance with bar marks, a salmon filet will go directly onto the belt of the Spiral Oven. As the product ascends to higher belt tiers, any released juices will baste the product on the lower tiers. These juices are recaptured and can result in as much as a 3 percent higher yield as compared to a linear system where basting occurs, but also falls into a drain. In addition, the super-heated vapor cooking environment of the Spiral Oven increases the efficiency of the energy transfer to the product. This results in added color development and yield as compared to running the Oven in Roast mode only. This results in juicier, tastier grilled salmon, for example, that is sure to please customers.

Automatic Filling Yields Faster Results

To take with them during travel and for dining at home, consumers could purchase ready-to-eat single-serve pouches of flaked fish or surimi. The slide fill mechanism of the Marlen Volumetric Filler makes possible the gathering of hot or cold, moist products for consistent filling into the most common packaging formats. The Marlen solution is known for handling tough applications that are often referred to as “hand fill only” products, such as fine, medium, or course shredded meats, flaked fish, shredded surimi, and more.

To save labor and provide accurate, repeatable results, the Marlen 4- and 6-PAK fillers use an automatic process which achieves fill weight accuracy with as low as one standard deviation equal to ±2% the target fill weight. This eliminates product giveaway and increases profits. The fill weights are easily adjusted manually (or via the optional servo motor) to maintain a tight range in sealed package weights. Package weights are repeatable and consistent, production run after production run.

The Marlen filler can be integrated with rotary or linear pouch sealers (simplex or duplex). In addition, Marlen’s 4- and 6-PAK fillers can be designed to seamlessly integrate with thermoform fill and seal equipment. Food processors can expect accurate product placement into packaging formats with the Marlen Industrial Filler solution, reducing seal contamination found in manual processes.

There are many industrial food processing equipment solutions offered by Marlen that result in increased yields, product uniformity and higher profits. To find solutions that fit your processing plant’s needs, Marlen’s website guides processors to the right fish and seafood processing equipment based on your specific application(s) for value-added products.