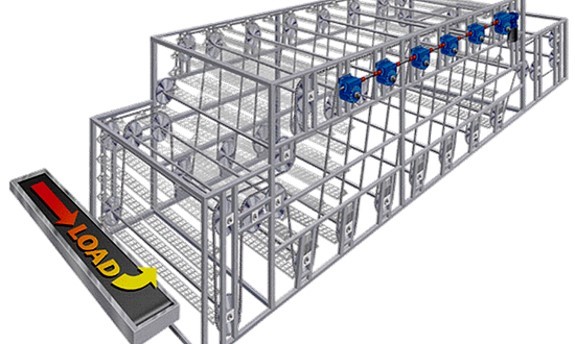

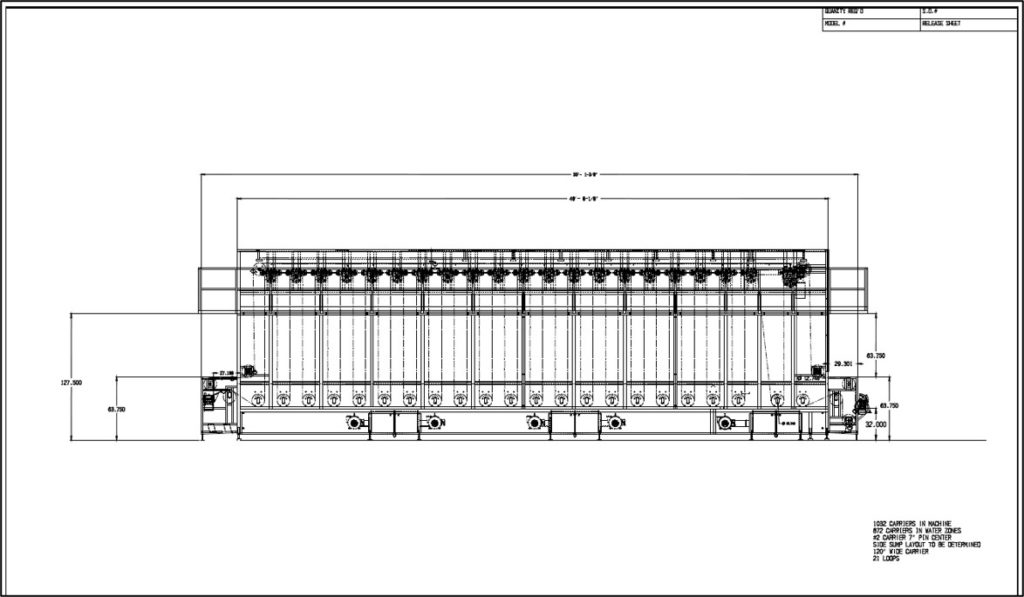

Serpentine Continuous Cook & Chill System

With separate cabinets designed to water or steam cook and chill via water, brine or glycol, our serpentine continuous cooking and chilling systems are ideally suited for large volumes of similar type of meat and poultry products such as slicing logs, turkey breast, molded products, D-shaped products, ground beef chubs, or pouched product. Capacity ranges from 2,500 to 20,000 pounds (1133 to 9071 kgs) per hour. The serpentine continuous flow process delivers the best product uniformity in the industry. Every piece of product travels through the same process conditions throughout its cycle, resulting in exceptional product consistency. This system can also be utilized for post-package pasteurization.

Are you interested in this product? We are here to help.

Contact Us

Featured Video

Serpentine Continuous Cook and Chill Systems Video