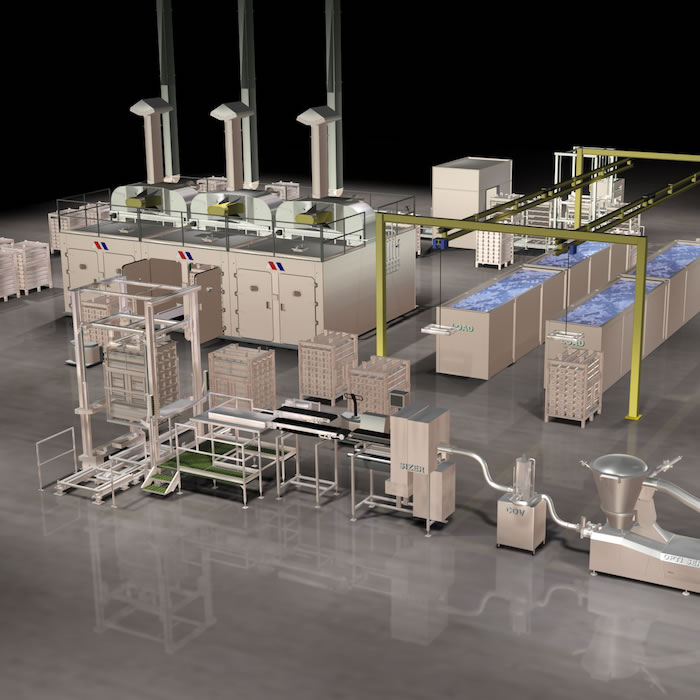

- Improve slicing yield by 5% or higher over end fill mold type systems

- Improve thru-put with faster load and unload time and fewer employees

- Molded Product decreases casing variations thus improving product uniformity

- Custom Designed around your product, process and facility

- Designed and constructed to maximize uptime through easy operation and maintenance with less labor

- Top loading mold is easier to load/unload

- No lids to handle; Mold lids are built into the rack

- No spring loaded lid to compress; Springs are permanent in rack

- Product can be stuffed in casing and held for molding at any time

- Product is stuffed at higher rate thus, reducing labor hours as stuffing rate increases/hr

- Made in the USA

Unload station – standard features:

- Two molds can be unloaded simultaneously

- Vacuum cups “grip” product for removal

- Compressed air lifts product from the molds

- Manual operation molds slide in and out-No lifting of molds!

- Take-away conveyor transfers molded product

- Complete with vacuum pump system

Load station – standard features:

- Control operation using electric push buttons

- Ergonomic design for loading molds into rack

- System raises and lowers rack for loading each level thus eliminating lifting the molds

- Hydraulic operation

- Epoxy coated hydraulic power unit

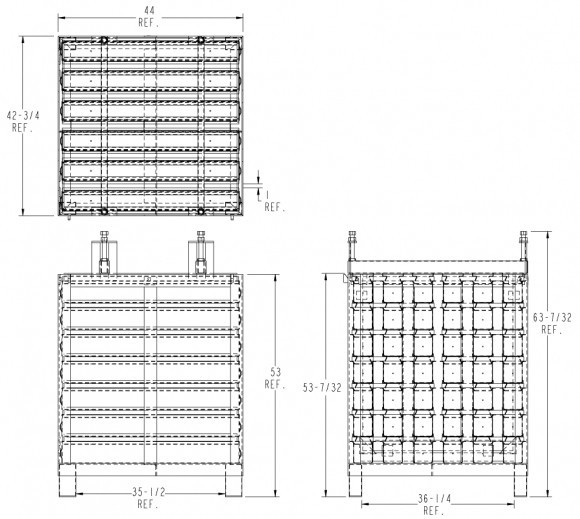

Press rack – standard features:

- Springs provide uniform pressure to all levels

- Custom designed to fit within existing cooking equipment