Spiral Ovens such as those developed and manufactured by Marlen convey food upward by a continuous conveyor belt that travels in multiple, circular tiers within the oven enclosure. Spiral cooking provides several benefits over cooking in linear ovens or traditional batch ovens. For example, a minimal footprint, versatile heating, increased product yield, greater product consistency, and improved energy efficiency are all advantages of Marlen’s spiral oven cooking solutions

Because of these benefits, industrial spiral cooking has been adopted as the continuous cooking system of choice among many ready-to-eat food processors. This allows processors the versatility to roast, steam, bake, broil, or even post-package pasteurize products in a single piece of equipment. Examples of the products range from baked goods, meatballs, chicken wings, oven-roasted vegetables, steamed chicken breast, and pasteurized pet treats.

Versatile and Compact Continuous Cooking

Because of the spiraled configuration of the oven belt, industrial spiral cooking maximizes the amount of product that can be cooked within a given footprint as compared to other cooking systems, such as an industrial microwave or linear belt cooker. Let’s take a look at how equipment sizing is determined for a linear cooking process. Often times the length of the linear oven or belt width will need to be extended to increase this throughput, which in turn increases the area in the plant occupied by the linear oven. In contrast, a spiral oven’s capacity and throughput can be achieved by simply adding to the overall belt width and length and increasing the number of belt tiers inside the oven. While this makes the equipment somewhat taller, the advantage of a small footprint is retained, which increases the utilization of the production area. In some cases, a single spiral oven could take up only 20 percent of the space required for three linear ovens to produce the same output.

Spiral Cooking Increases Product Yield

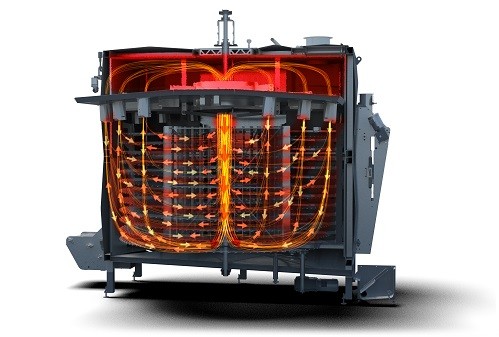

While saving production floor space in a facility, continuous cooking with industrial spiral ovens also has the advantage of increasing product yield versus more traditional cooking methods like batch ovens or linear cookers. For example, when cooking proteins, the spiral oven conveys the product upward via a continuous conveyor belt that travels in multiple, circular tiers within the oven enclosure. As protein products travel upward through the spiral oven cooking process, fat is rendered from the ascending product and bastes the product on the lower belt tiers. In this manner, the product is cooked in its own juices, providing the taste, aroma, and appearance of a traditional, home-cooked product. Since a portion of the rendered fat is recaptured in this basting process, the result is an increase in overall product yield as compared to a traditional linear cooking process where the fat is rendered but goes straight to the drain. Further, a common advantage of the spiral oven enclosure with a sloped floor is to collect the remaining rendered fat as a ready-to-eat byproduct from the cooking process that can be sold or reused.

Greater Product Consistency

Continuous processing almost always equates to consistent results. Consistency of cooking is another important advantage of an industrial spiral cooking process. In the spiral oven, each product travels on a conveyor belt through the same exact cooking conditions. The same can be true for a linear cooking system; however, because of the limitations of a linear footprint, a wider belt is preferred over a smaller opening for a narrower belt, which creates a challenge for heating evenly across a wider belt as compared to a spiral oven belt which is commonly narrower. On the other hand, batch cooked products are racked, which by its design makes controlling the final product difficult because the product position is static on the rack and does not allow for even cooking of all products. This inconsistency is more apparent at higher cooking temperatures like roasting or baking where the temperature differential between the heating source and the recipe setpoint can be 50 to 100 degrees difference versus the “Steam Mode” of a spiral oven where the setpoint and steam temperature are relatively equal. These aspects of the batch cooking process not only detract from product quality, but also reduces product yield, particularly when production is ramped up or a higher cooking temperature is necessary.

Improved Energy Efficiency

Due to the smaller footprint and compact design of spiral ovens, industrial spiral cooking also has the advantage of providing improved energy efficiency over linear and batch cooking solutions. Spiral ovens consume significantly less energy than the linear oven, for example, and are more efficient in terms of labor costs compared to rack ovens. Being compact, fewer personnel are required to produce the same output and less time is required for cleaning.

Enhanced Food Safety

While having the advantages of increasing product yield in a smaller footprint with greater product consistency and improved energy efficiency, spiral ovens also enhance food safety as the ovens can be set to temperatures that eliminate bacteria in food products by steaming or using uniform dry heat. The oven’s control system automatically adjusts energy levels to maintain a consistent operating condition within the oven’s housing, allowing food processors to validate lethality protocols. Outbreaks associated with L. monocytogenes have prompted governmental regulatory agencies to impose stricter regulations, especially for ready-to-eat foods. Marlen’s control system and specially designed airflow provide a uniform heat treatment system, bi-directional airflow, optional servo belt control, and data-logging for pasteurizing post-packaged products. Using higher temperature regimens of 195°F to 205°F (90.6°C to 0.1%), Marlen can obtain significant reductions of L. monocytogenes (~2 log) within 2 to 4 minutes with most products. Producers are using spiral ovens to post-package pasteurize products to extend shelf-life and reduce the risk of product recall. The spiral design couples with Marlen’s spiral chilling solutions if required for an optimal, continuous, turnkey system that makes great utilization of production area with its reduced footprint.