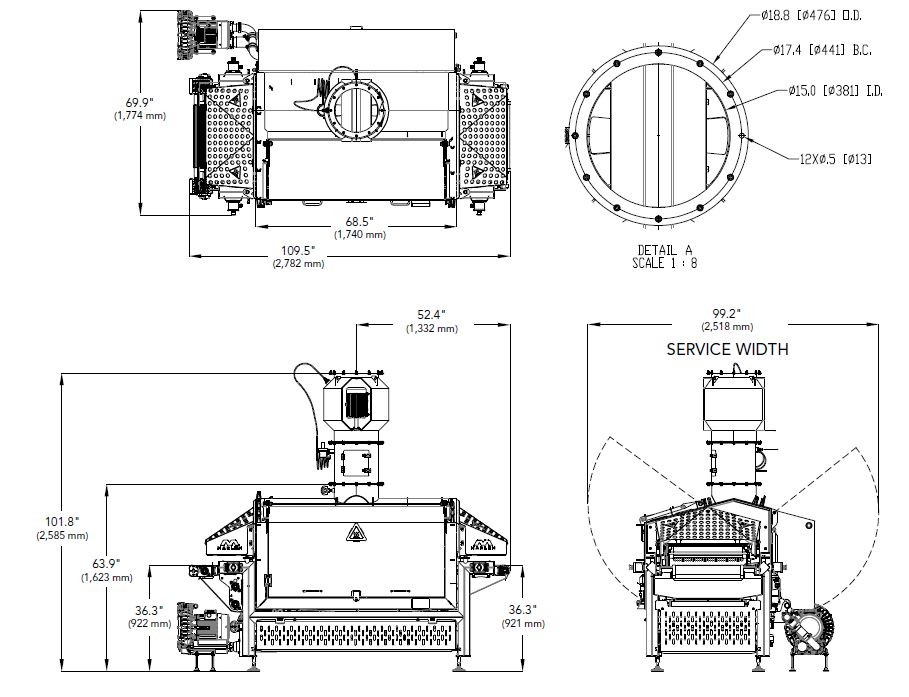

Footprint

9.08' (2.76 m) L x 8.25' (2.51 m) W x 8.5' (2.59 m) H

Belt Width

24" (600 mm) overall; 22" (558 mm) useable

Conveyor Height

33.5" (850 mm)

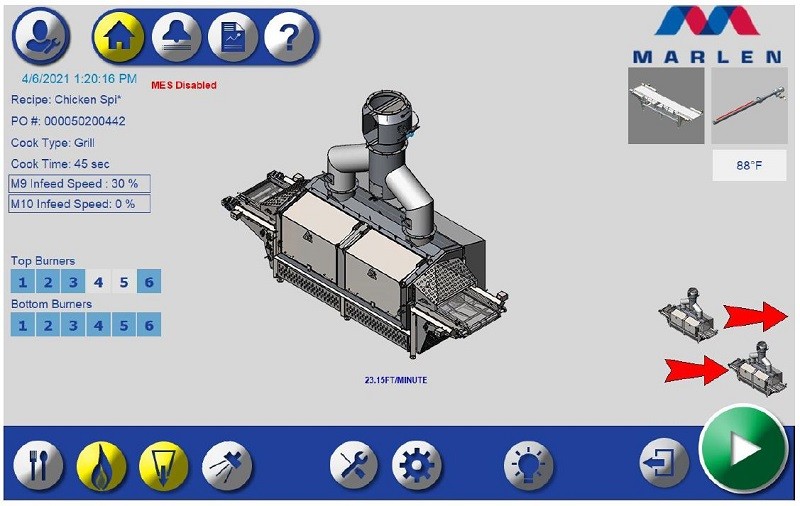

Conveyor Speed

15-120 second dwell time average; Up to 80' (24 m) per minute

Product Clearance

Up to 5" (127 mm)

Gas Supply

Up to 1.75 MBTU/Hr @ 2 PSI (7 PSI max.); 1.25" NPT *Most recipes utilize only 30-80% of the burner capacity

Electrical Supply

USA: 480V AC, 3 Ph, 30 Amp, 60 Hz / EUR: 380V AC, 3 Ph, 35 Amp, 50 Hz

Extraction

15" (381 mm) outlet; Up to 3,500 CFM (120 m³/min.) total outlet; Up to 6,000 CFM (170 m³/min.) total

Drains

Overflow – 3" (75 mm) sanitary

Water Supply

1/2" (12 mm) NPT inlet; Up to 90 GPH (340 liter/hr)

Steam Supply

1" NPT (25 mm) inlet 150 lbs/hr (70 kg/hr) Overheat Protection System. If equipped with Steam Impingement Option: 1.25" NPT (32 mm) inlet 650 lbs/hr (295 kg/hr) @ 40 PSI (3 bar)

Ethernet (EWON)

1 x Ethernet cable CAT6 for remote monitoring