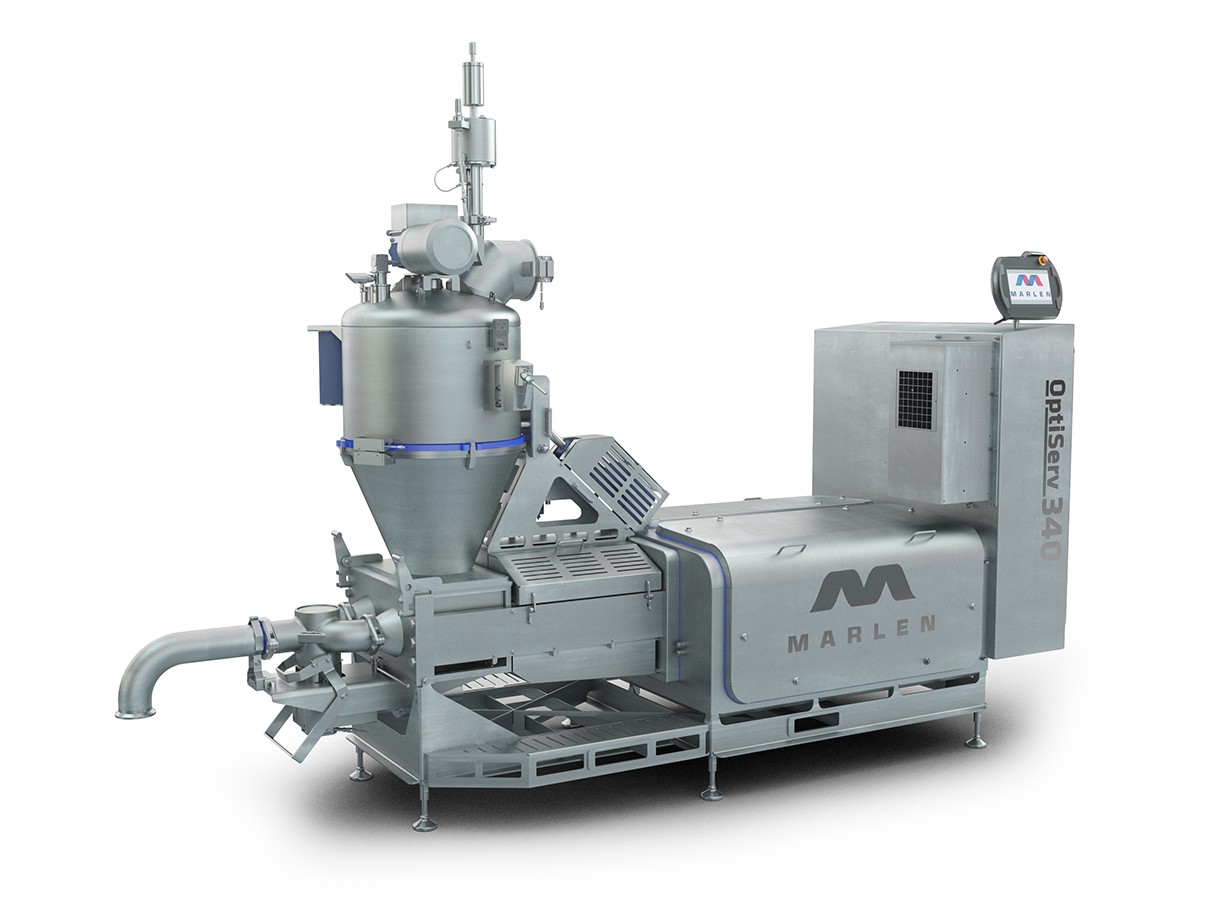

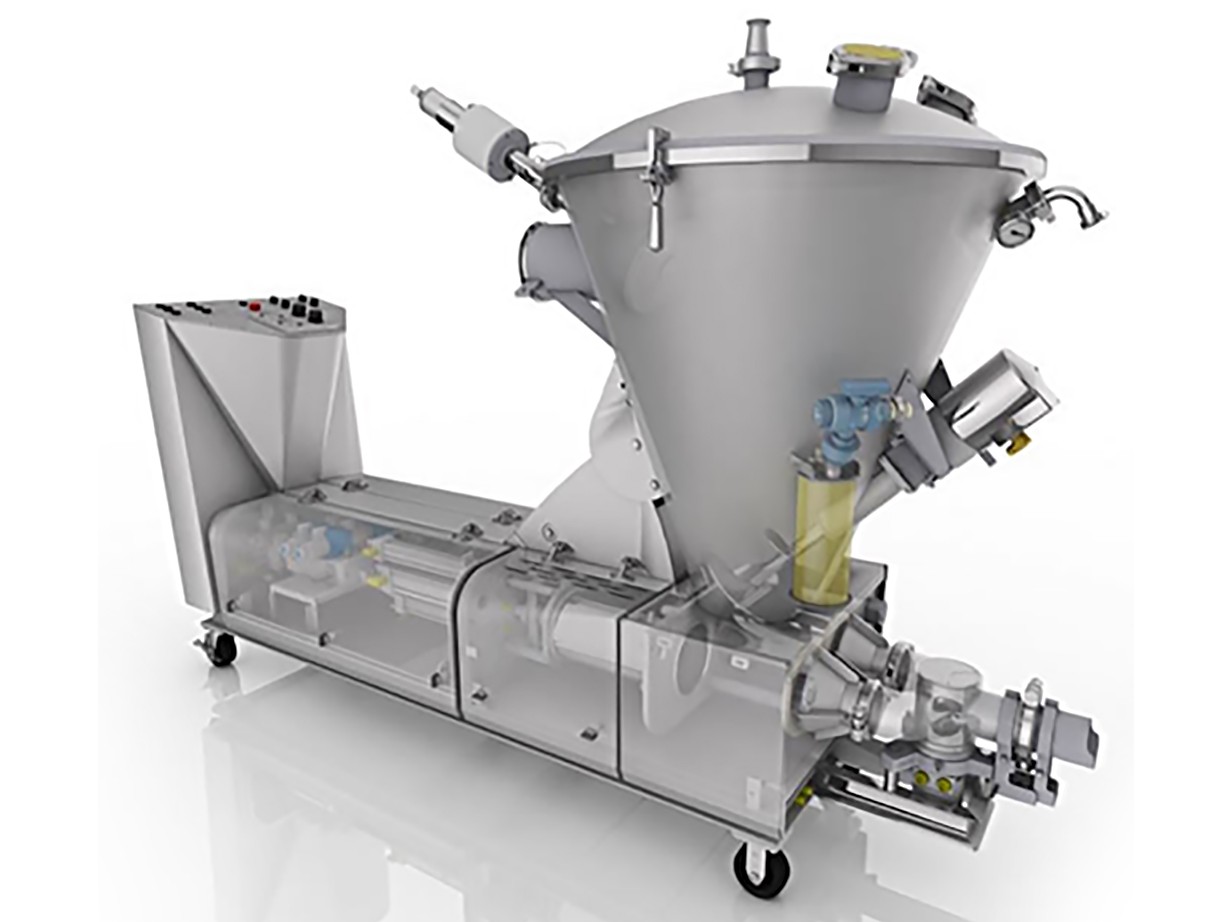

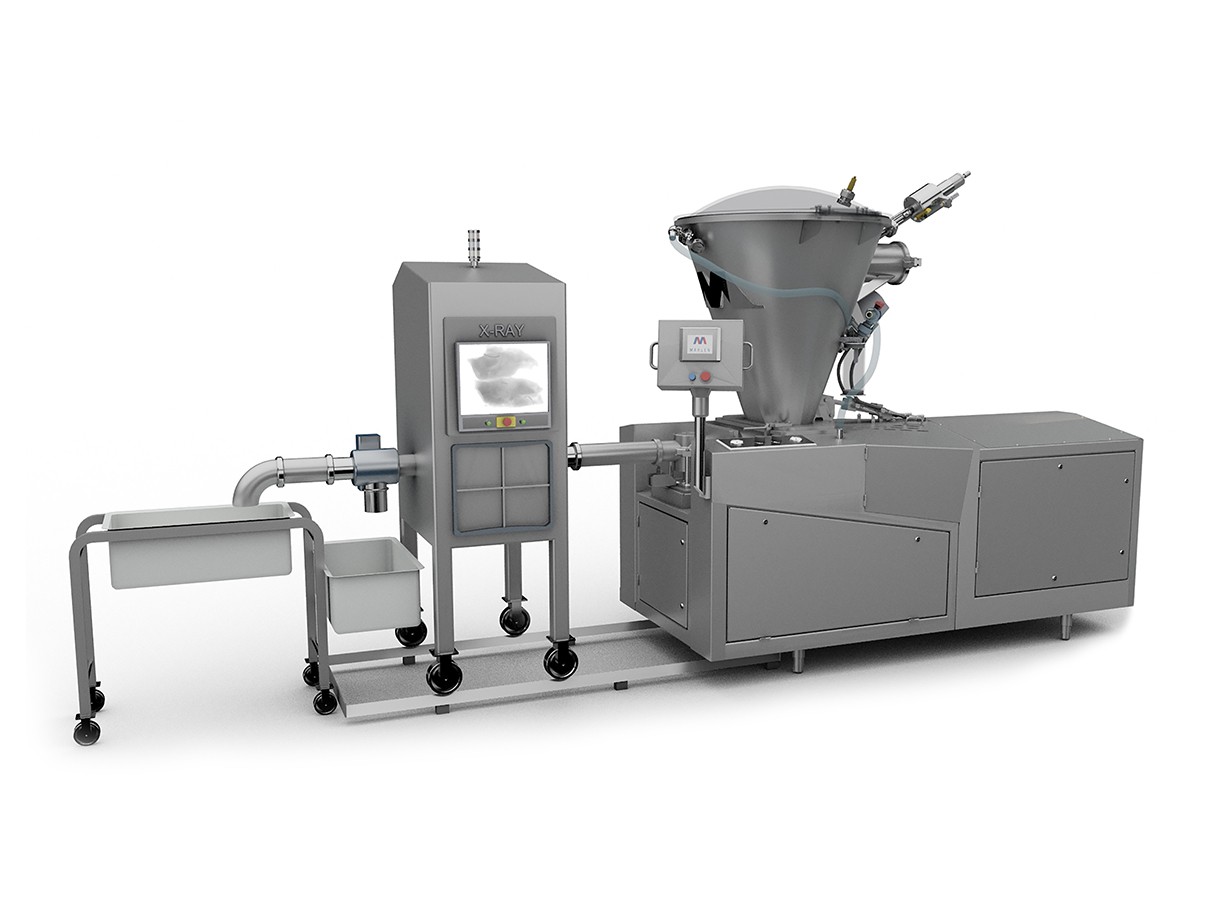

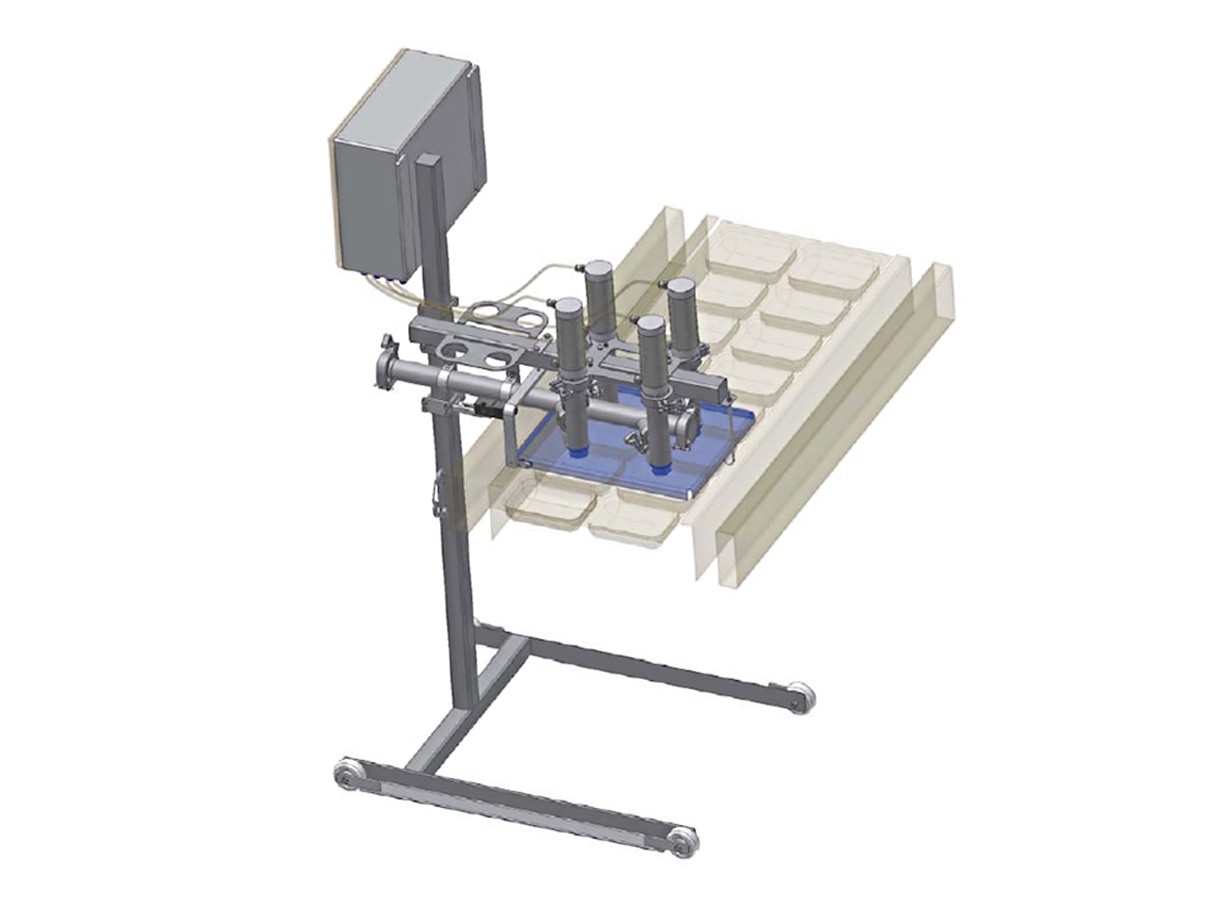

Opti series vacuum stuffing and pumping systems are ideally suite for whole muscle, sectioned, formed and emulsified meat and poultry products along with products such as sliced peaches, diced tomatoes and lobster filled ravioli.

Industries and applications in Marlen vacuum stuffing, pumping and portioning solutions are typically used include:

-

Food

-

Fruit Veggie

-

Meat Poultry Fish

Marlen’s Opti series vacuum stuffers and pumps can be equipped with a variety of hopper options designed to match application and product requirements. Please view each of our available products for full details. For additional information, Contact Us Today.